What is simulated process printing? A breakdown by a screen-printer.

What is simulated process printing?

A breakdown by a screen-printer.

Simulated process screen-printing is a specialized technique used in the world of t-shirt printing. It is a printing method that produces complex and detailed images on garments by using a series of stencils, layers, and colors. This type of printing has become increasingly popular over the years, and it is now a go-to method for many companies, including South Prairie T-shirt co., for creating high-quality, photorealistic designs on t-shirts, hoodies, and other types of apparel. In this article, we will delve into the world of simulated process screen-printing, discussing what it is, how it works, and its benefits for businesses and customers.

What is Simulated Process Screen-Printing?

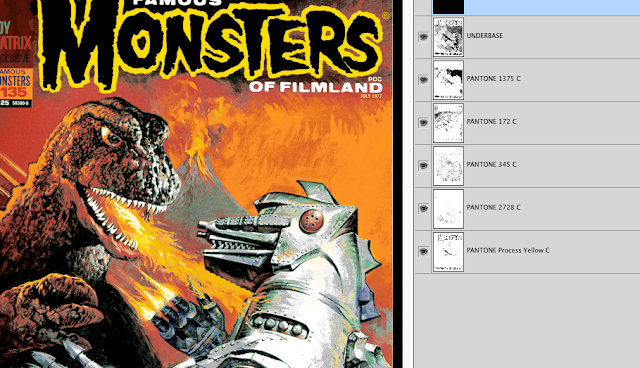

Simulated process screen-printing is a printing technique that involves using a combination of halftone layers (dots of varying sizes) to recreate full-color images on garments. It is often touted as the most advanced form of screen-printing and is commonly used for printing on dark and colorful garments. This technique uses up to ten colors to achieve a full-color effect, providing a vast range of colors and shades, giving a photorealistic result to designs that cannot be achieved with other printing techniques.

How Does Simulated Process Screen-Printing Work?

Simulated process screen-printing uses a series of stencils, a printing press, and a combination of halftone layers to produce its final result. The process starts by creating a digital image of the design that needs to be printed on the garment. This image is then separated into different color components, which is crucial for printing on dark and colored garments.

Each color component then goes through the halftone process, where it is broken down into tiny dots of varying size. These dots represent the different shades of the color used in the design. The smaller the dot, the lighter the shade it represents, and the larger the dot, the darker the shade it represents.

After the halftone process, each color component is transferred onto a separate stencil. This stencil is then placed onto the garment and aligned accordingly. As the printing process begins, the garment is placed onto the printing press, which has a series of screens with the stencils attached. Each screen is responsible for transferring one color component onto the garment. As each layer of color is added, the final result is a combination of all the halftone layers, creating a full-color image on the garment.

Benefits of Simulated Process Screen-Printing for Businesses

1. Unmatched Detail and Vibrancy

One of the significant advantages of simulated process screen-printing is its unmatched ability to produce intricate and detailed designs on garments. This technique uses a vast range of colors and shades to create a photorealistic effect, making it perfect for designs with intricate details and numerous colors.

Moreover, simulated process screen-printing is the go-to method for printing on dark and colorful garments without sacrificing the vibrancy of the design. Other printing techniques might struggle to produce vibrant and detailed designs on dark-colored apparel, making simulated process screen-printing the preferred choice for many businesses, including www.southprairietshirts.com.

2. Cost-Effective for Large Orders

Another benefit of simulated process screen-printing for businesses is its cost-effectiveness when dealing with large orders. This printing technique is ideal for printing bulk orders, as it requires minimal setup time and labor, making it a more affordable option compared to other printing methods.

3. Durability

With simulated process screen-printing, the ink is directly embedded into the fabric of the garment, making it more durable than other printing methods. This means that the designs will last longer and withstand multiple washes without fading or cracking, providing businesses with a high-quality finished product that will please their customers.

4. Ability to Print on Different Types of Fabric

Unlike some printing methods that are limited to specific types of fabric, simulated process screen-printing can be used on a wide variety of materials, including cotton, polyester, and blends. This makes it a versatile option for businesses that offer a range of clothing items.

Benefits of Simulated Process Screen-Printing for Customers

1. High-Quality Prints

Simulated process screen-printing is known for producing high-quality prints on garments that can accurately reproduce the finest details. This means that customers get to enjoy photorealistic designs that are sure to grab attention and make a statement.

2. Vibrant and Long-Lasting Designs

As mentioned earlier, simulated process screen-printing results in vibrant and long-lasting designs on garments. Customers can rest assured that their designs will retain their vibrancy even after multiple washes and wear.

3. Wide Range of Colors and Shades

Another benefit for customers is the vast range of colors and shades that can be achieved with simulated process screen-printing. This allows for more creative and detailed designs, making it a popular choice for those looking to print intricate designs on their garments.

4. Affordable Option for Large Orders

For customers looking to place bulk orders, simulated process screen-printing is a cost-effective option as it incurs lower setup costs and requires minimal labor. This translates to cost savings for businesses, which can be passed on to the customers, making it an affordable option for large orders.

In Conclusion

Simulated process screen-printing is a highly sought-after printing technique that produces photorealistic and detailed designs on garments. Its unmatched ability to create vibrant colors and intricate details make it the go-to choice for businesses and customers alike. With its durability, versatility, and cost-effectiveness, simulated process screen-printing is a valuable addition to the printing industry and a favorite among companies, including South Prairie T-shirts.

With its ability to accurately reproduce gradients and subtle shifts in color, it offers a more realistic and visually appealing final product. Combined with its cost-effectiveness and flexibility, simulated process printing has become a popular choice for creating high-quality designs, and South Prairie T-Shirt Co. is at the forefront of this printing technique. Visit www.southprairietshirts.com to learn more about their simulated process printing services and how they can help bring your designs to life.

South Prairie T-Shirt Co. takes pride in their expertise and use of cutting-edge technology to achieve the best results for their clients. Their simulated process printing services make it possible to print designs with a high level of detail at an affordable price. Whether you are a business looking to create custom shirts for a promotional event or an individual wanting a unique design on your t-shirt, South Prairie T-Shirts has got you covered.

custom shirts near me, calgary alberta shirtrs, canada screenprinter, custom t-shirts calgary

Got something you want to have printed on a shirt or hoodie?

contact us today at sales@southprairietshirts.com

visit our website www.southprairietshirts.com

check out our instagram www.instagram.com/southprairietshirts

visit our website www.southprairietshirts.com

check out our instagram www.instagram.com/southprairietshirts